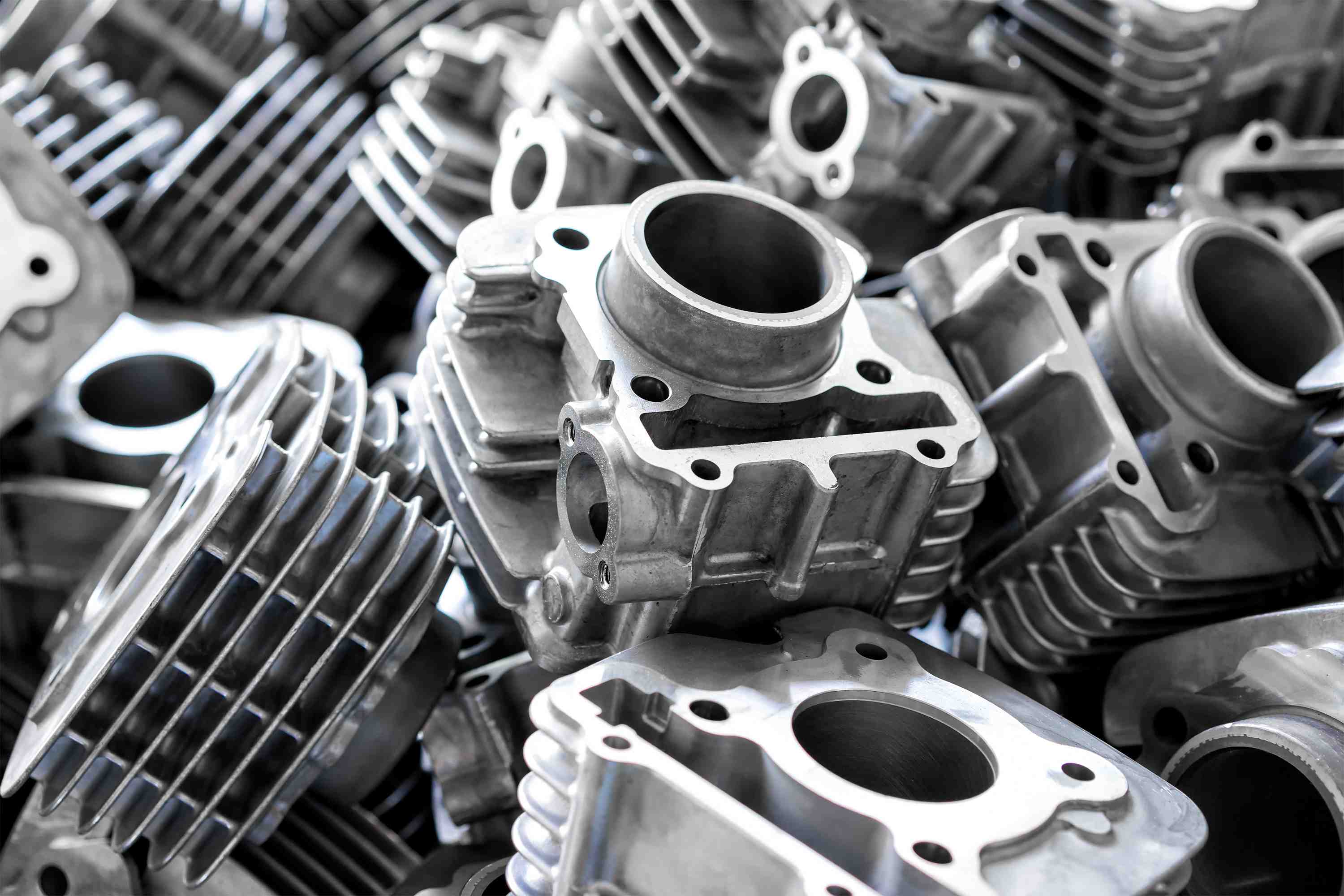

Die Forgings

CAB Worldwide elevates the benchmark in the forging industry with exceptional solutions that merge top-notch quality, profound expertise, and expansive global coverage. Our vast experience across an extensive array of metals, alongside robust collaborations with ISO-certified foundries globally, guarantees the delivery of forgings with unmatched quality and precision. Our portfolio spans various industries, from Hydraulic & Industrial to those with the rigorous standards of the automotive sector.

We excel in a comprehensive range of forging techniques including Open and Closed Die Forging, Warm Forging, Hot Forging, and Cold Forging. With CAB Worldwide, you gain a partner whose capabilities are as diverse as they are advanced, ensuring your projects are realized at the highest standards.

Why Forging is the Superior Choice

Opt for forging to benefit from unmatched strength, durability, and material integrity. The forging process aligns metal grains under high pressure, producing parts that outperform in resistance to impact, fatigue, and wear. With minimal defects and superior performance in harsh conditions, forged components are ideal for applications requiring robust components, from automotive to aerospace and beyond.

Benefits of choosing forgings Over Castings

Forging offers several advantages, including:

01

Increased Strength and Durability: The forging process enhances the metal's internal structure, yielding parts that are stronger and more durable than castings.

02

Higher Material Integrity: Forged parts have fewer surface and internal flaws, such as voids, leading to better overall quality and performance.

03

Better Thermal Resistance: Forgings can withstand higher temperatures and harsher environments, maintaining their integrity under thermal stress.

04

Precision and Customization: Forging allows for precise control over part dimensions with less waste, facilitating customization to specific design needs without extensive post-processing.

In the ever-evolving landscape of forgings, CAB Worldwide stands at the forefront as a global leader, delivering unmatched quality across a broad spectrum of forging techniques. CAB's mastery over numerous metals has enabled the cultivation of robust relationships with over 36 ISO-certified facilities across the U.S., China, India, South Korea, and South Africa. This expansive and strategic alliance positions CAB to uniquely cater to the varied needs of industries around the globe, ensuring precision, strength, and excellence in every forging project we undertake.

Mining & Aggregate Industry Components

Oil & Gas Components

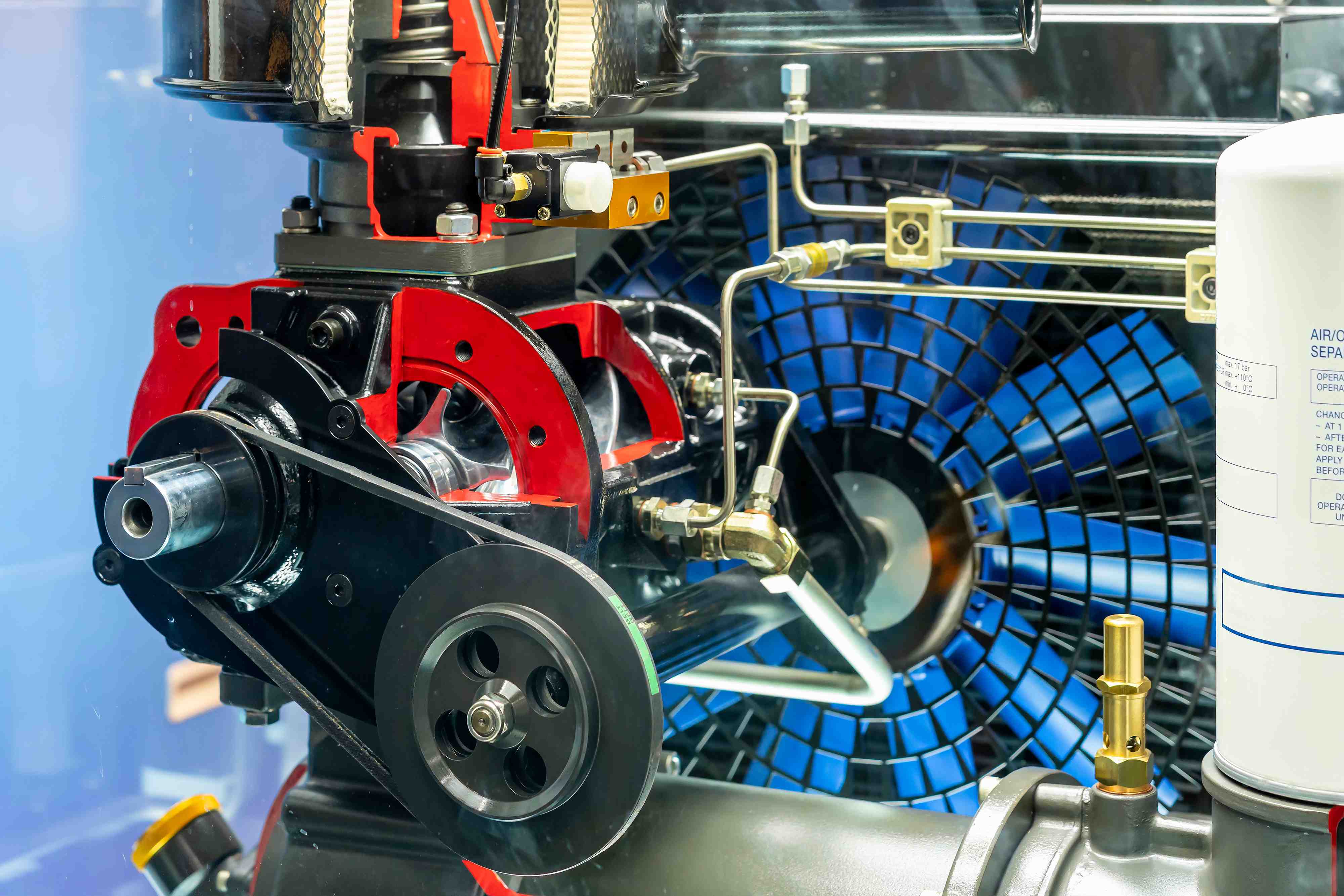

Compressor Components

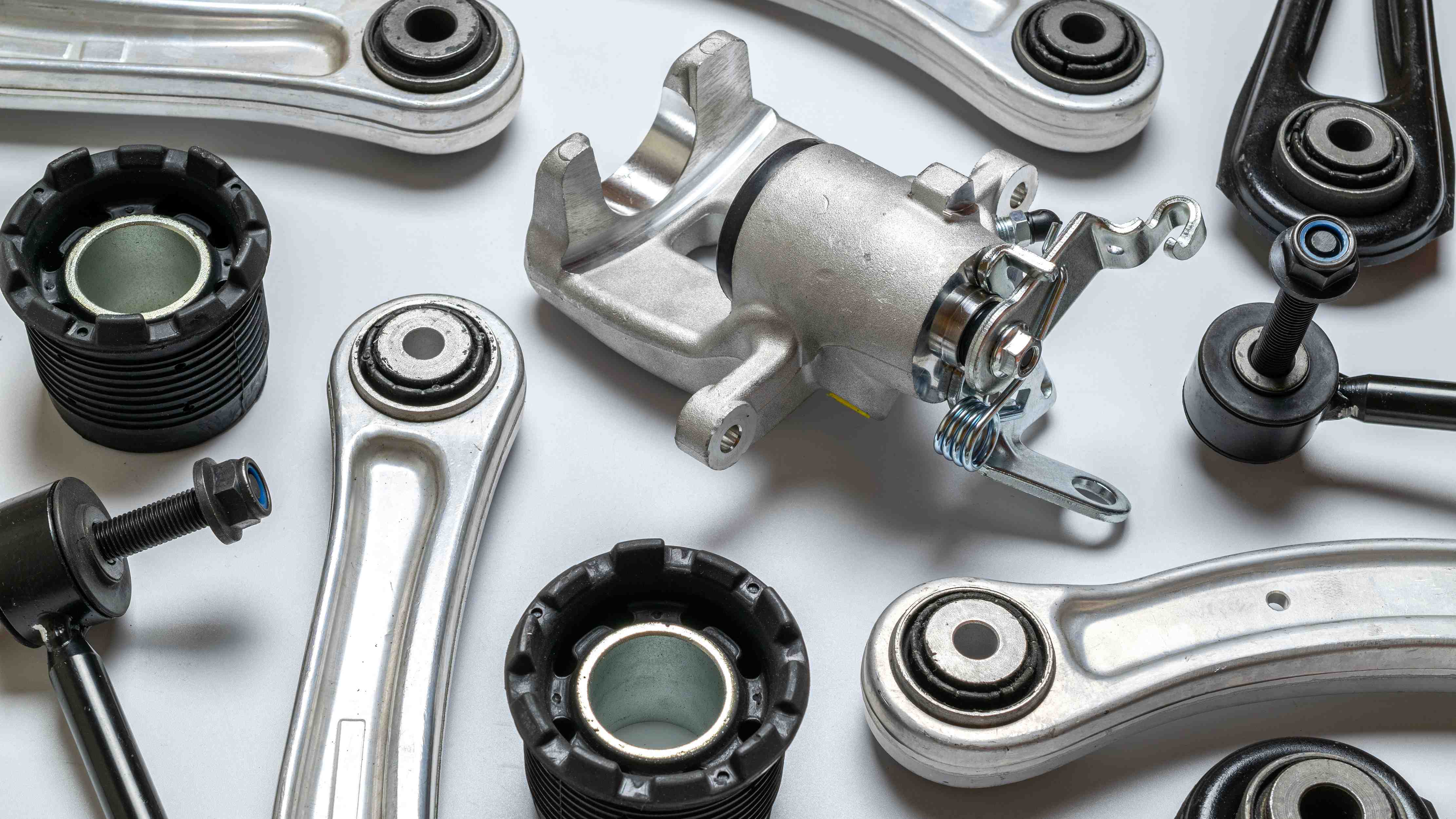

Automotive Components

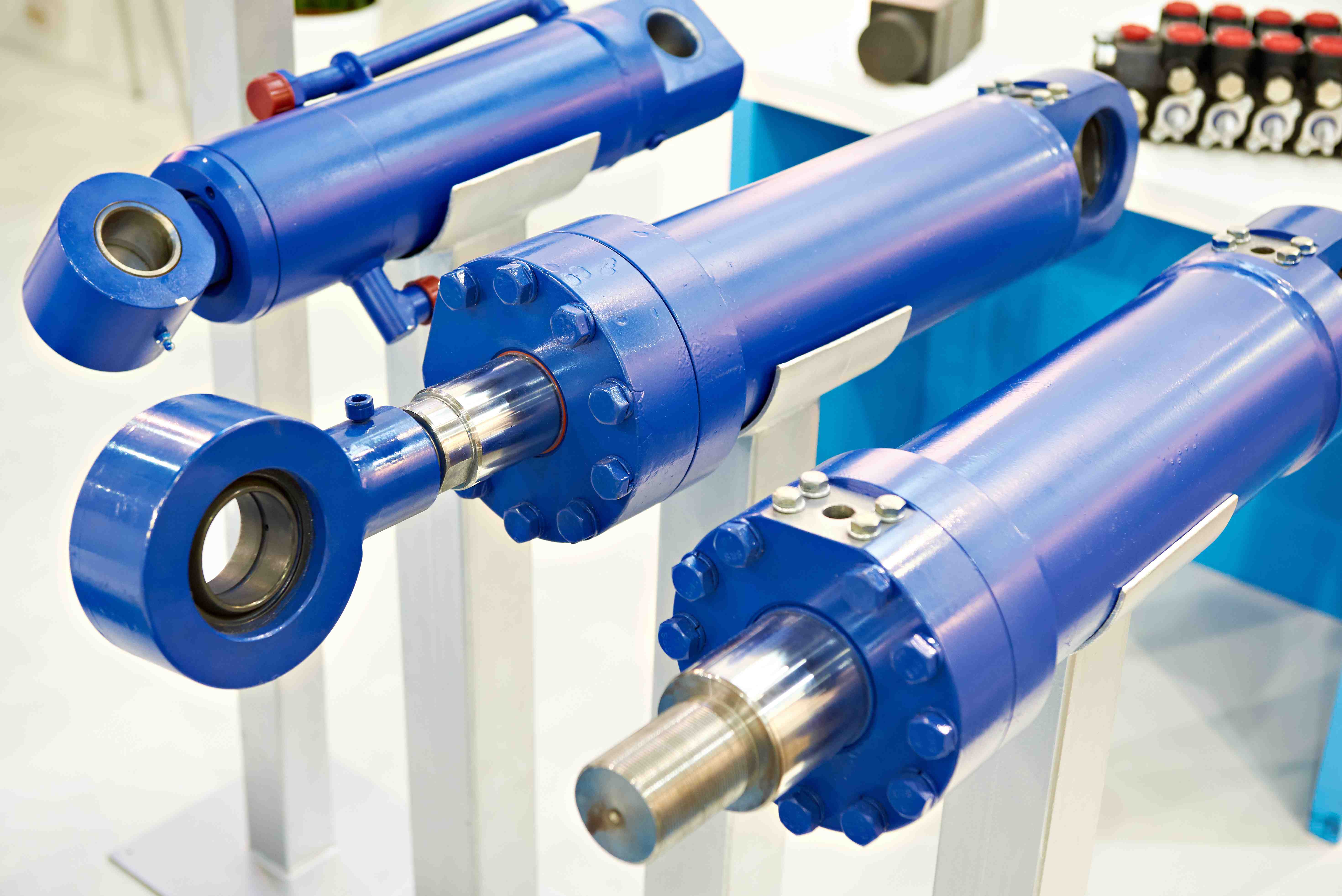

Hydraulic Cylinder and Actuator Components

Rolled Ring

Forgings

Die Forgings

Non-Ferrous Castings

Cast Irons

Steel Sand & Investment Castings

Here at CAB Worldwide, we deliver precision-crafted forgings tailored to diverse industry needs