Excellence Engineered

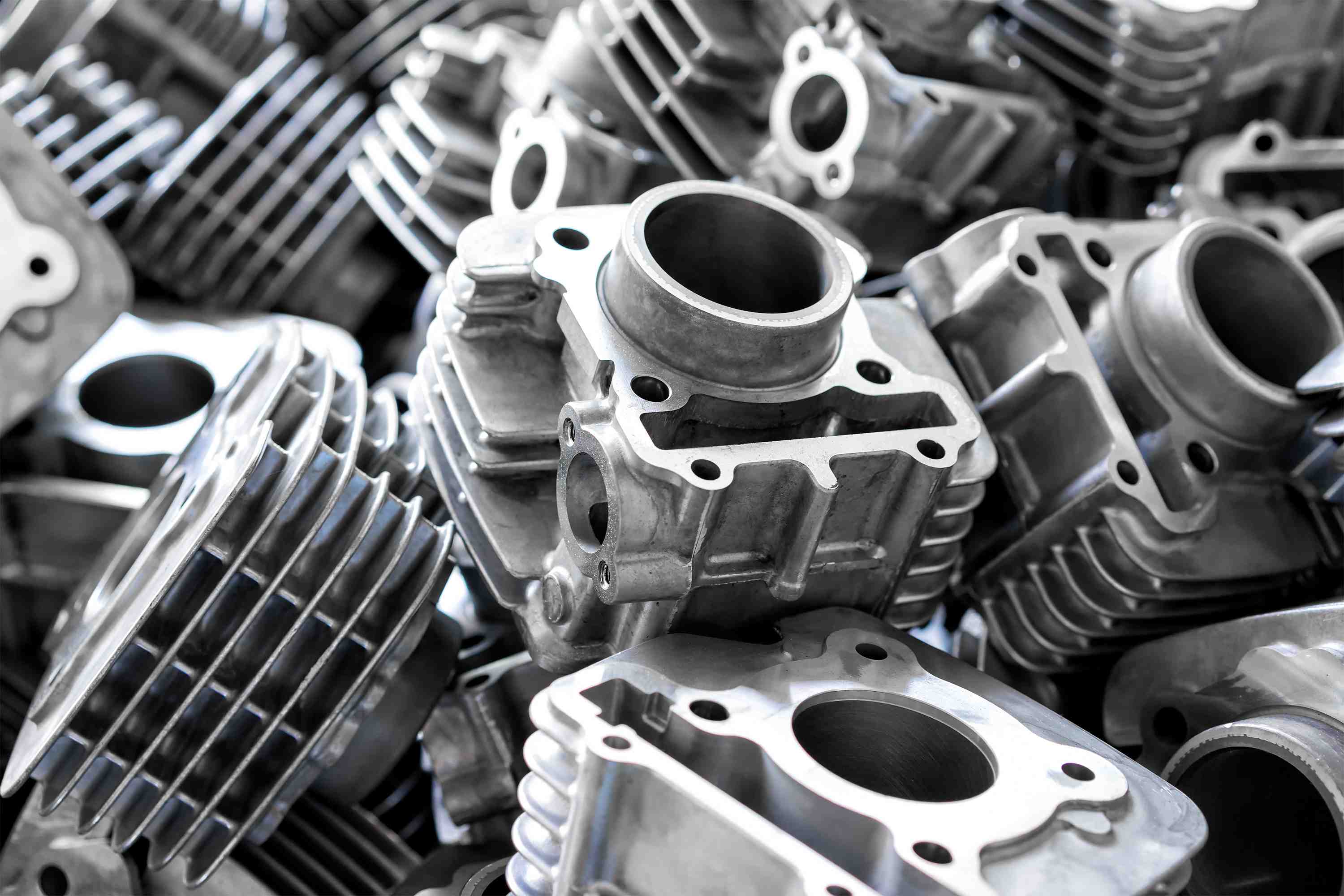

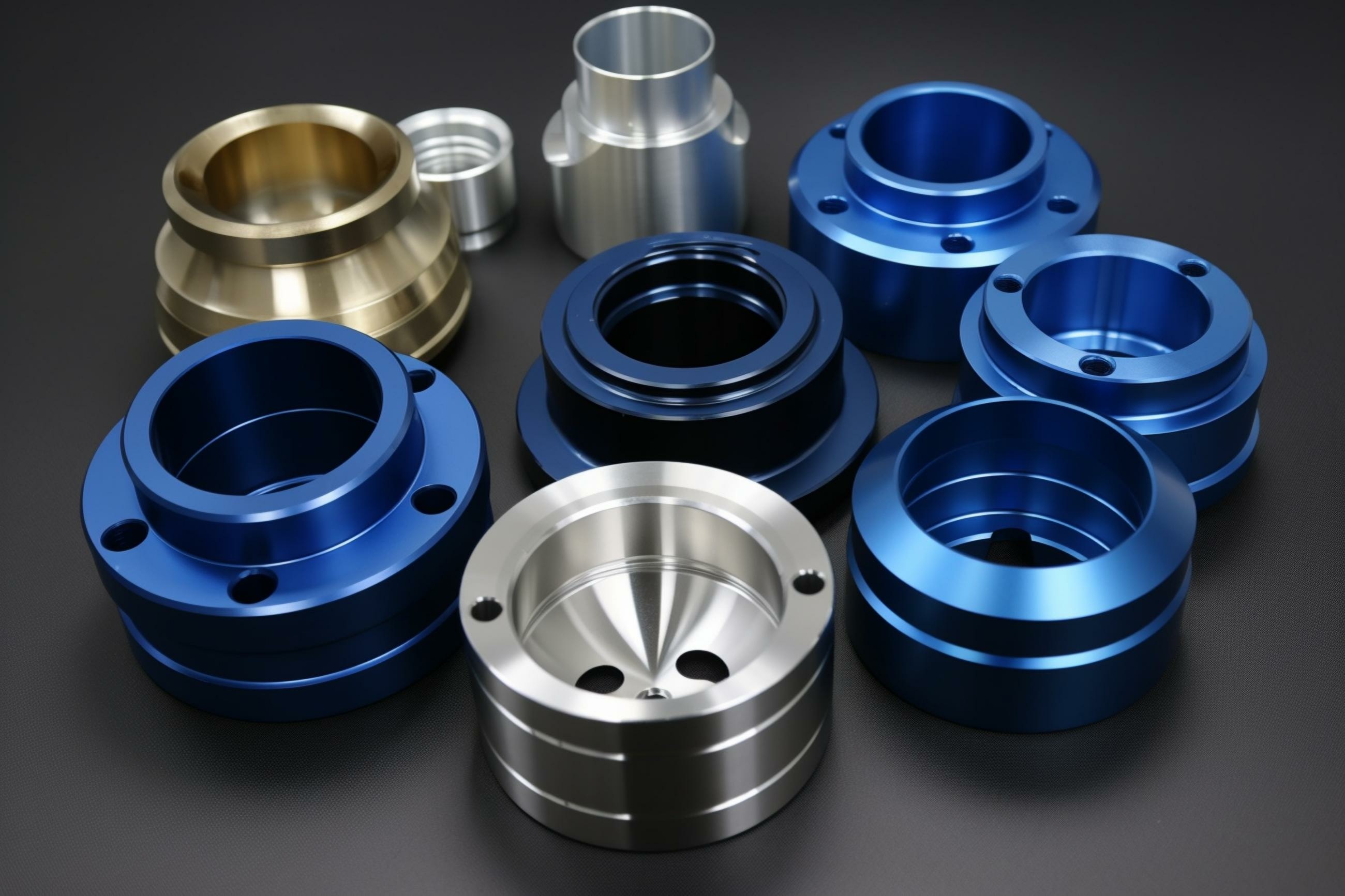

Precision machined castings, Forgings, Fabrications and assemblies

CAB’s 40 years of global supply chain development and U.S. manufacturing offer expert solutions, prioritizing cost reduction and just-in-time inventory support across various products, from steel flanges to rail accessories and more.

Worldwide Engineering and Quality Teams

CAB’s global presence is bolstered by our experienced U.S., India, and China engineering and quality teams enabling swift and efficient customer and supplier collaboration. Let CAB simplify your complex projects.

Engineering excellence

diversified supply chain

commitment to quality

The CAB Difference -

Risk Mitigation Excellence

At CAB, we know how crucial it is to find the right balance between cost-effectiveness and productivity. That’s why we provide competitive offshore pricing alongside accessible local manufacturing choices. Whether local or global, our engineering expertise ensures streamlined operations. Need quick inventory or reliable support? We’ve got you covered locally, while our strong partnerships and experienced team ensure smooth project progression.

Customer care

TECHNICAL expertise

superior quality

DFM expertise

We Have expertise

The Foundation of CAB

Technical Expertise and Commitment to Quality Create a Strong Foundation

A strong team of exceptional engineers in key processes and products has positioned CAB as a vital contributor to our customers’ success. We firmly believe that providing the best service to our customers lies in meticulously controlled processes and an unwavering attention to detail.

Our engineers and our processes give our customers the resources and confidence with deep Design for Manufacturing experience. Our constant drive for improved process control and error proofing leads to repeatable high quality results – further driving out cost. This commitment to quality extends to every employee and partner within the CAB network, all of whom stand firmly behind our promise to ensure YOUR success.

Risk-Reducing Engineering

CAB Worldwide offers you innovative solutions and cost-efficient excellence – our products redefine competitiveness, delivering reduced total cost of ownership for your long-term success.

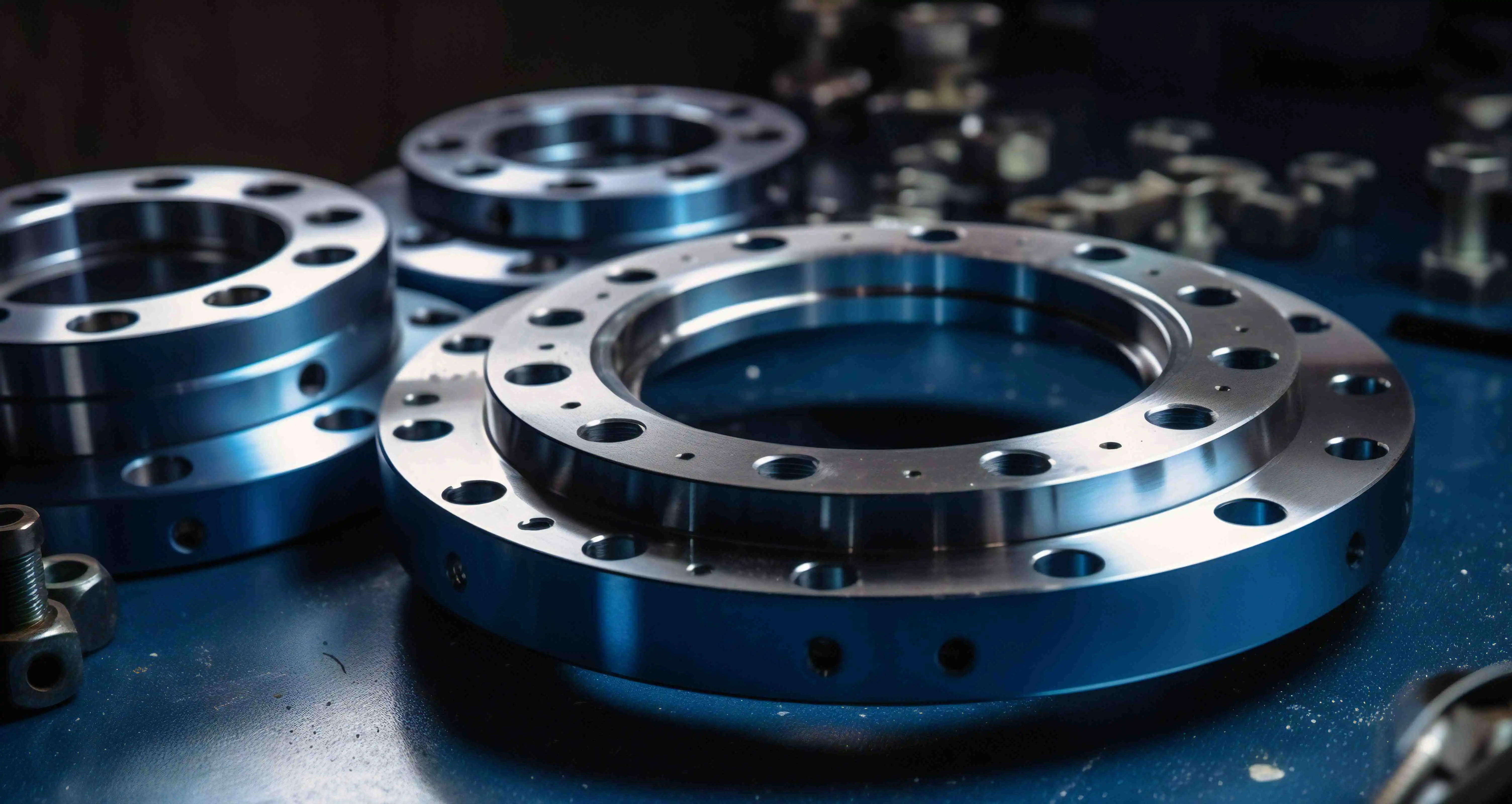

Casting / Forging / Fabrication

Steel Sand & Investment Castings

Cast Irons

Non-Ferrous Castings

Die Forgings

Rolled Ring

Forgings

Cold Forgings

Steel Pipe Flanges

AWWA

ANSI

ASME

OTHER

railroad accessories

Solid Manganese Frogs

Switch Points

Track Bolts

Joint Bars

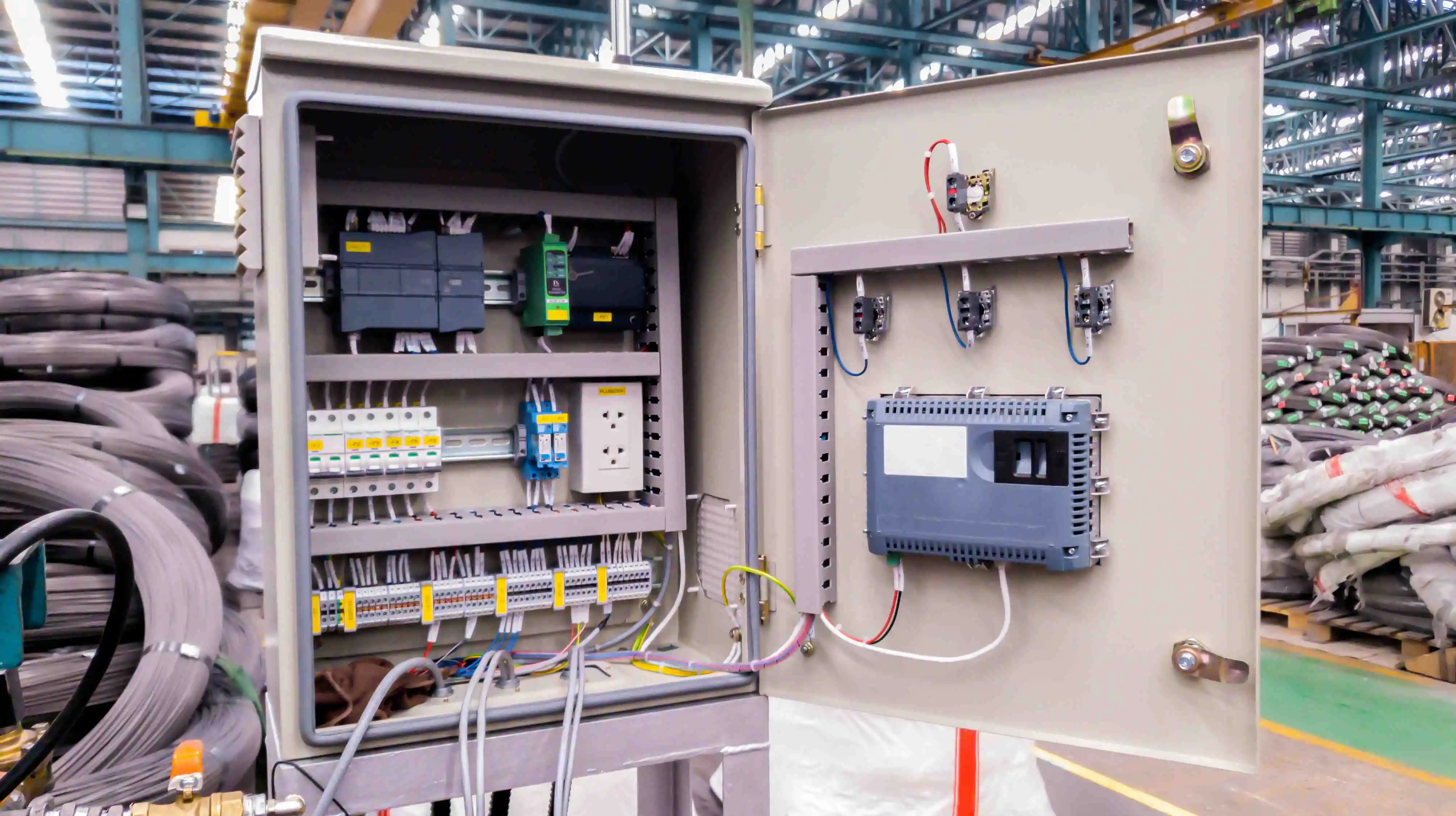

equipment enclosures and wiring assemblies

UL & NEMA Certified Enclosures

Control Panels

Custom Engineered Solutions

Premium quality

Reduce Your Total Cost of Ownership

CAB’s focus on optimized design, proactive problem-solving, and strict quality control effectively lowers the total cost of ownership by simplifying manufacturing process, error proofing, minimizing revisions, and ensuring product reliability, providing comprehensive solutions to save money, time, and management headaches.

Design for Manufacturing Advice

Regular Audits of Facilities and Processes

Training and Retraining on Process Controls

Global engineers overseeing process and production coordination onsite

Quality Assurance and Error Proofing Plans

US-based Inventory Programs Available

US-based Inspection and Value Added Services Available

Production Part Process per automotive level standards

hydraulics

Components & assemblies

Pipe Flanges

automotive & Components

mining

Rail Accessories

Equipment

Enclosures

Industrial

Components

Oil & Gas

Compressor Components &

Assemblies

OEM Components

Deep Industry Knowledge

Major Business Segments Served

THE FOUR "D"'s

Our Premium Supplier Selection Process

Are your customers shopping for lower costs? Better quality? Reduced lead times? Is it a new program launch? One of the most essential steps of supplier selection is determining the needs of the customer. It is during this phase when design requirements and expectations are communicated. This may involve details such as material grades, geometric tolerances, surface finishes, and testing/performance requirements.

Once all product requirements, quality expectations, and delivery timing have been communicated and defined, CAB will reference our Approved Supplier List (“ASL”) for the best source matching your specific criteria. Our ASL consists of many ISO9001 and IATF 16949 certified companies that have proven success on similar projects and have long-term relationships with CAB. You can rest assured that the chosen supplier has developed similar products and will be capable of meeting all criteria and expectations. Sources that have failed to be successful on agreed upon criteria are promptly removed from our ASL.