Steel Sand & Investment Castings

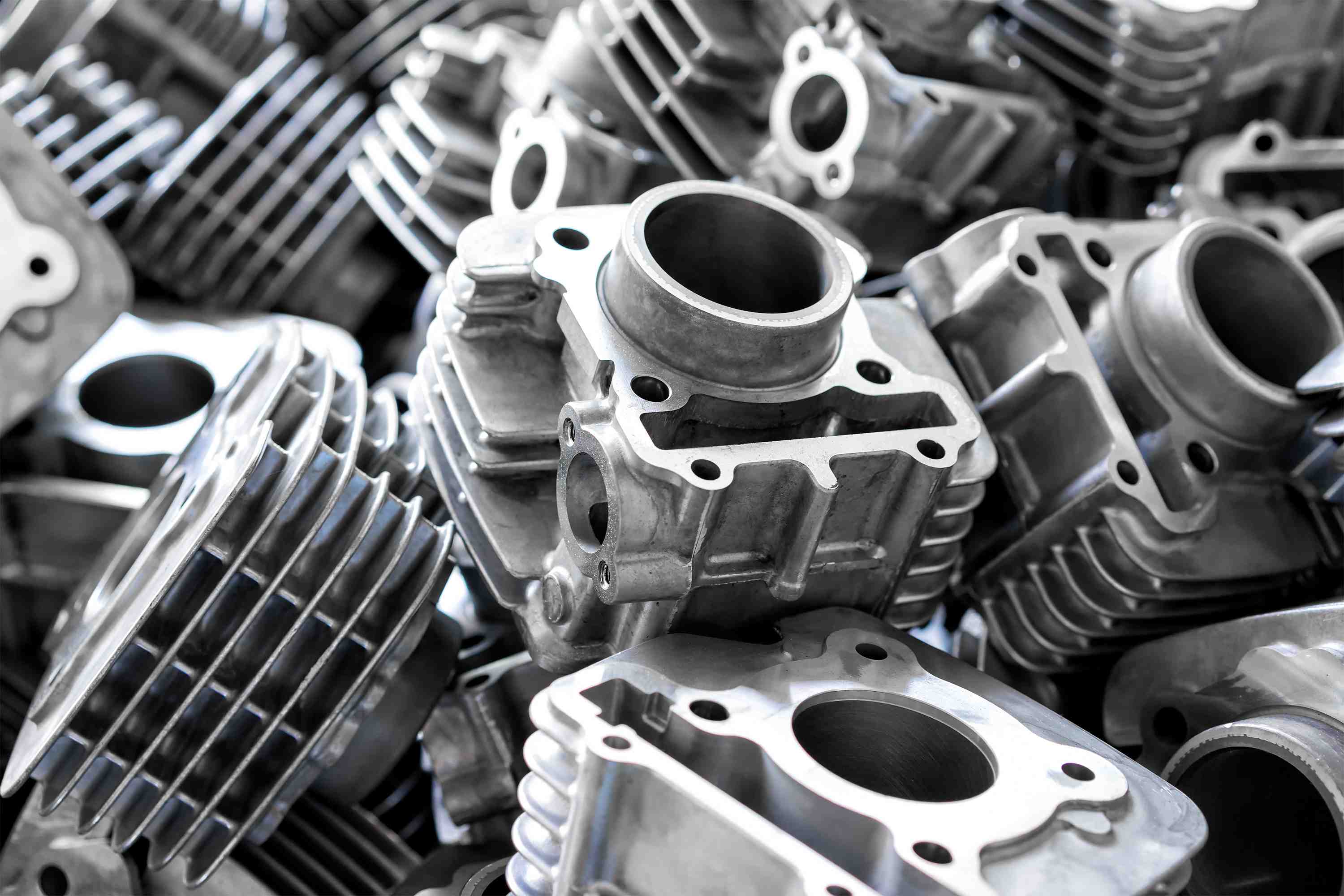

Sand casting, or sand molded casting, is a fundamental metal casting process employed by our metalworks team. Utilizing sand and binder as the mold material, CAB Worldwide’s skilled artisans craft steel sand castings by placing a pattern equipped with a gating system within the sand to form a mold. After removing the pattern, molten steel is poured into the mold cavity.

Upon cooling, the sand mold is disassembled, unveiling the intricately shaped steel casting. Ranging from 1 lb. to 1,000,000 lbs., our steel sand castings exhibit a spectrum of configurations, showcasing the versatility and precision of our craftsmanship.

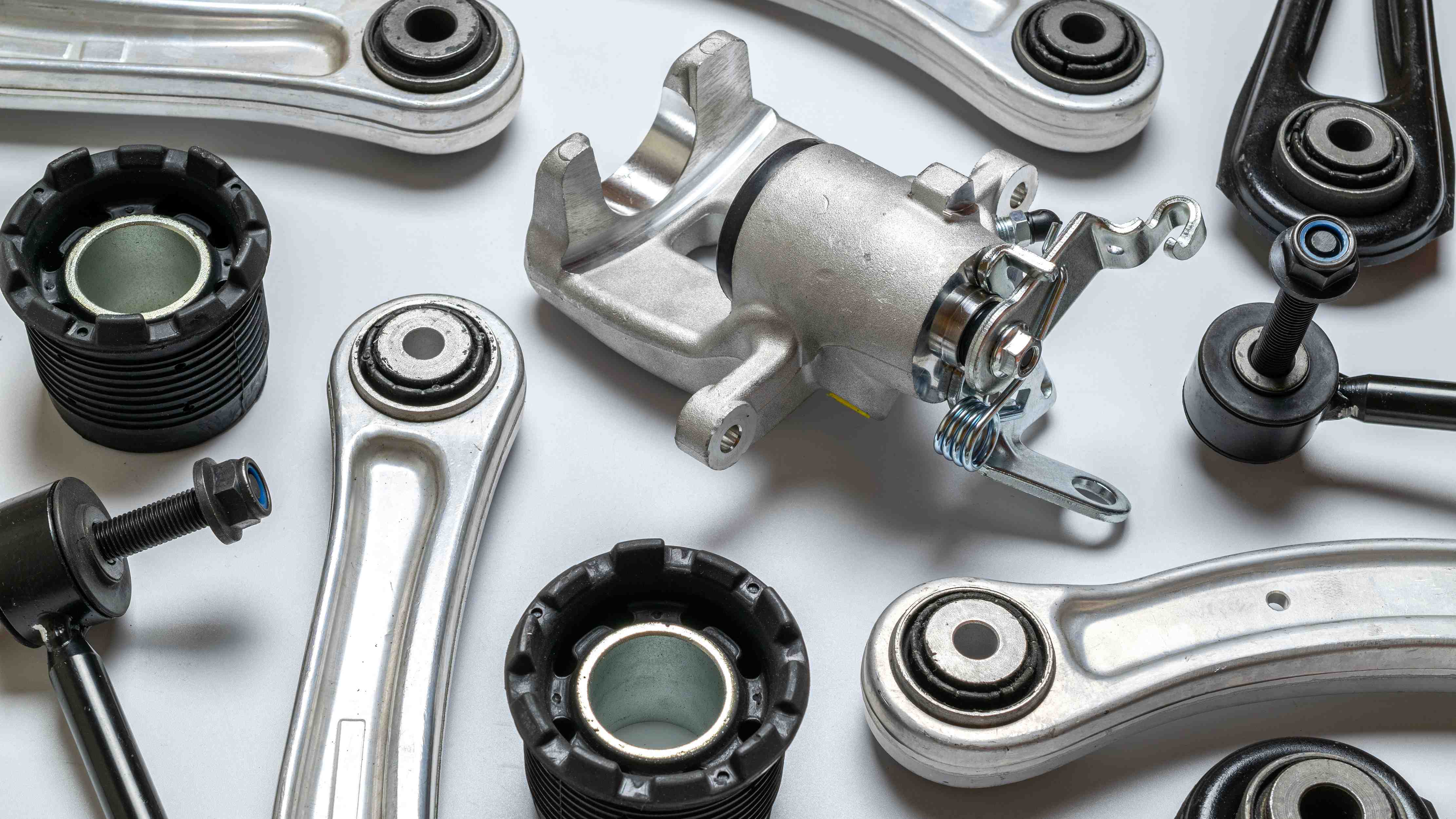

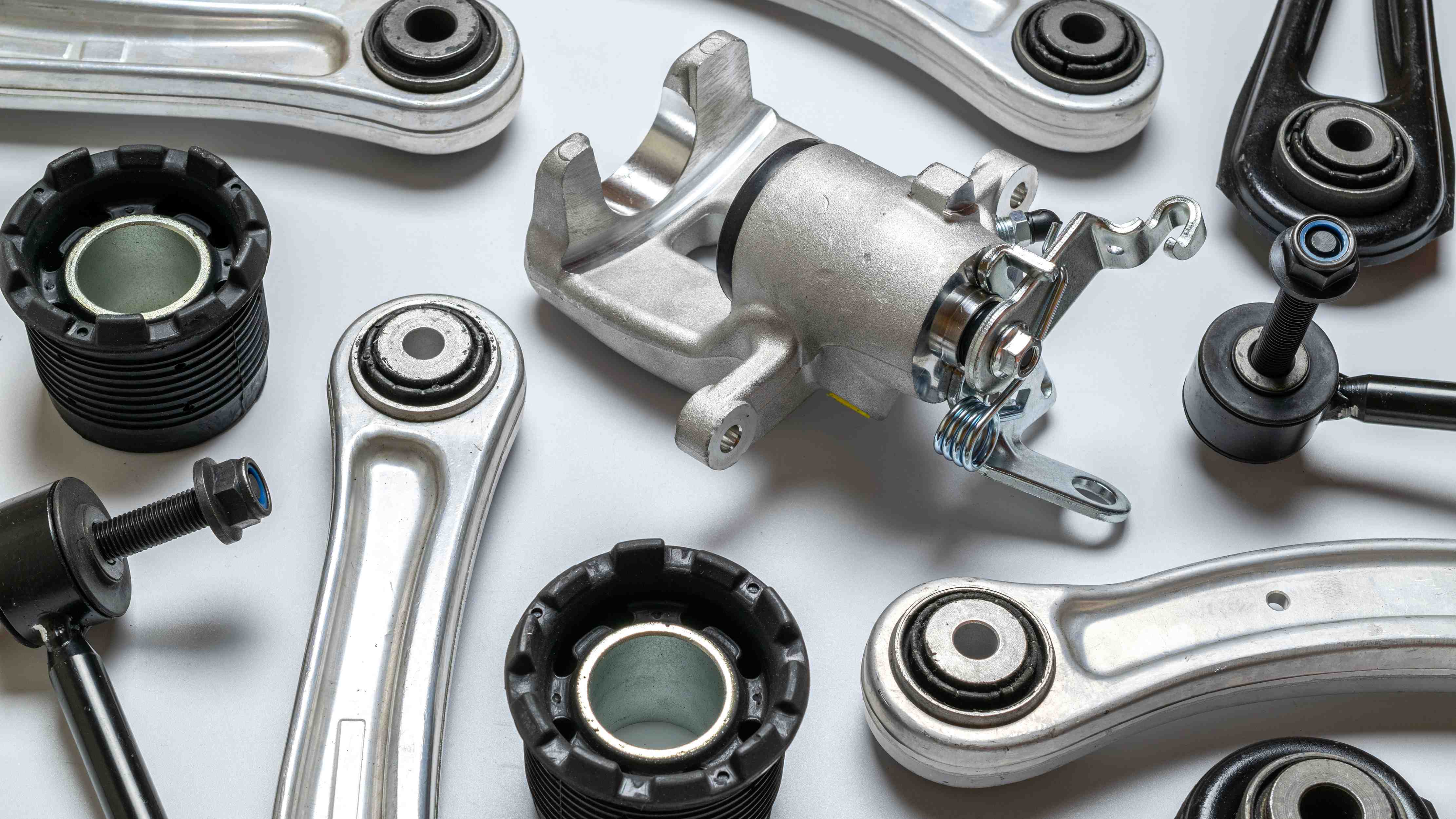

Automotive parts

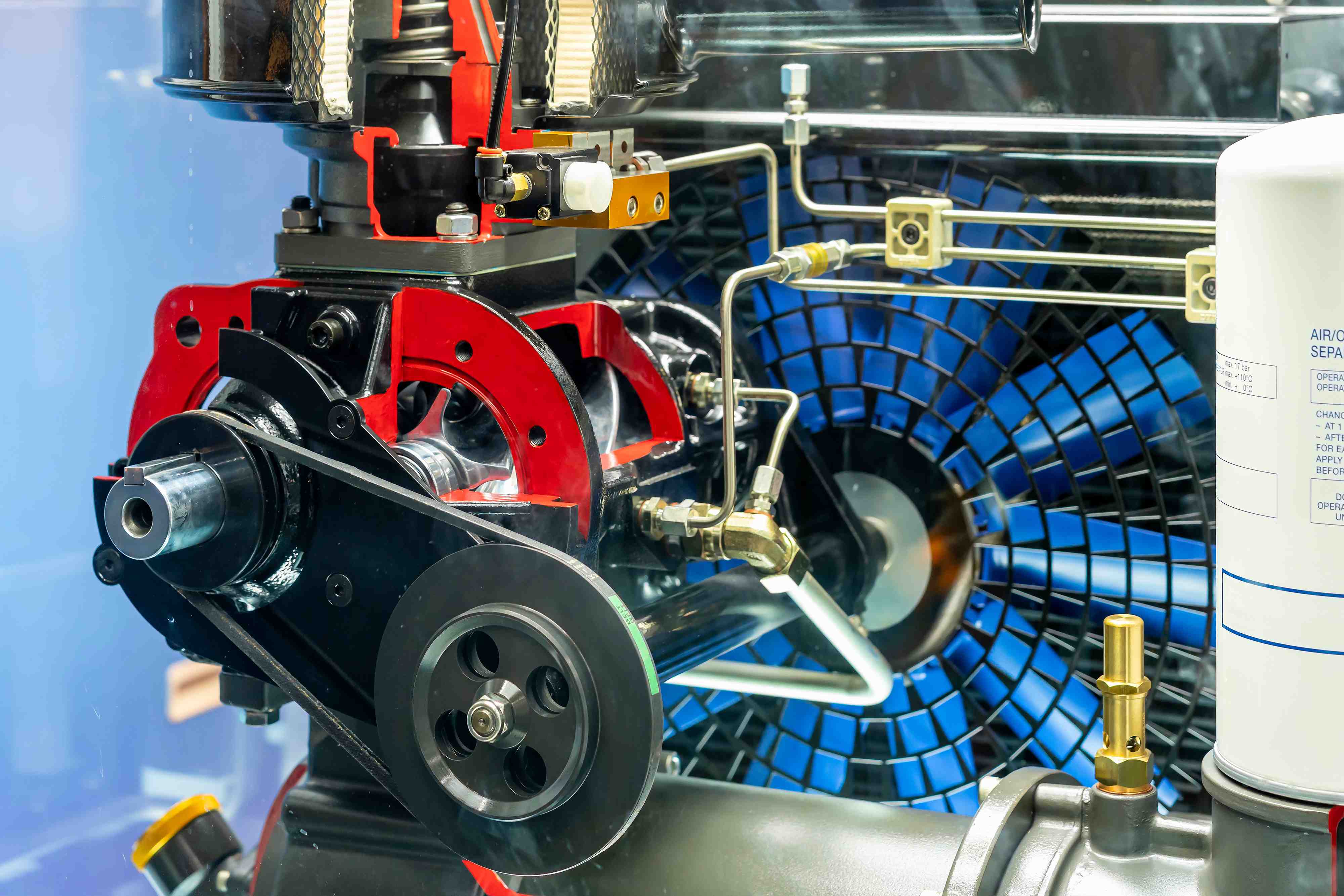

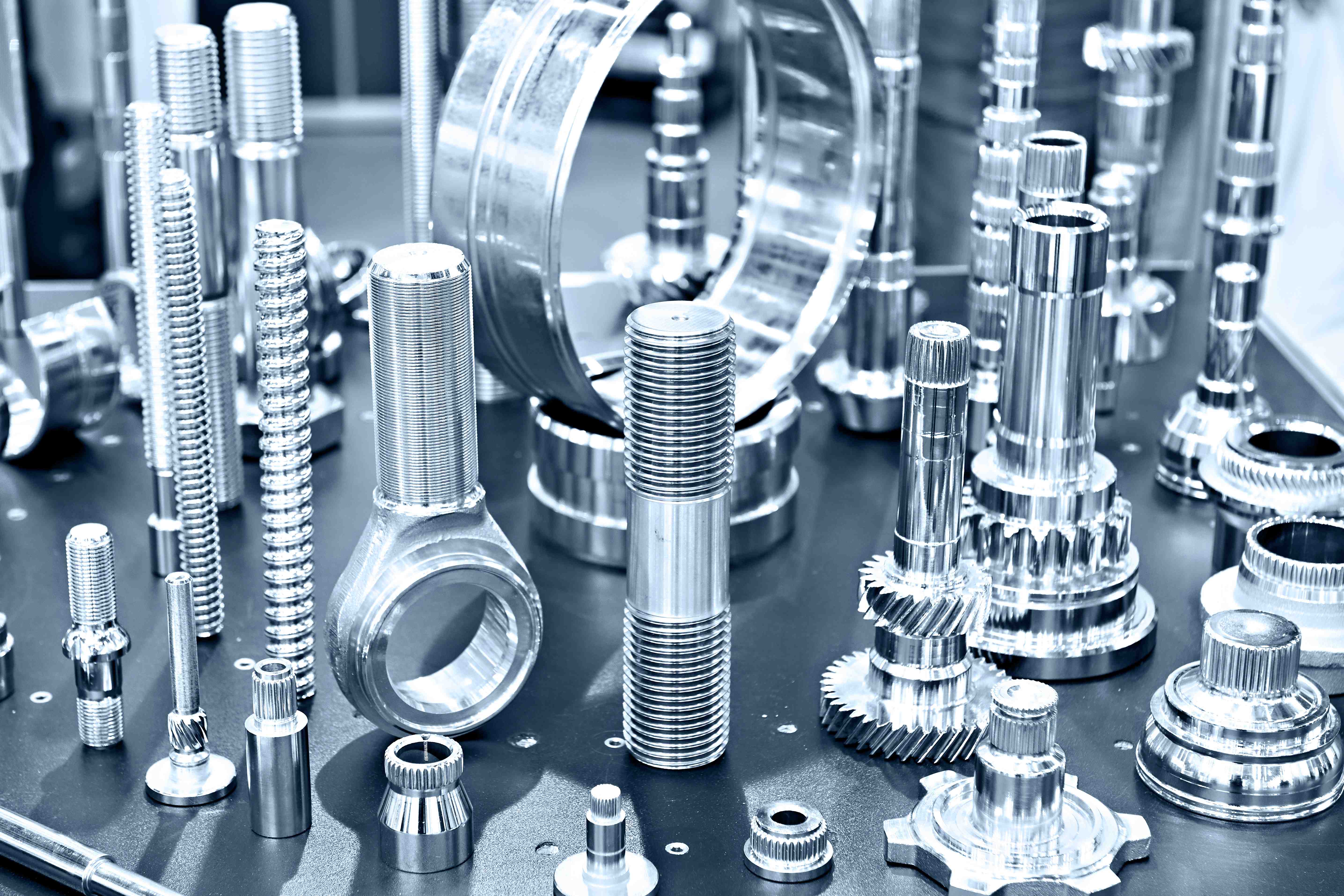

Industrial machinery components

Valves and Pumps

Aerospace components

Customized tools

Marine components

Railway components

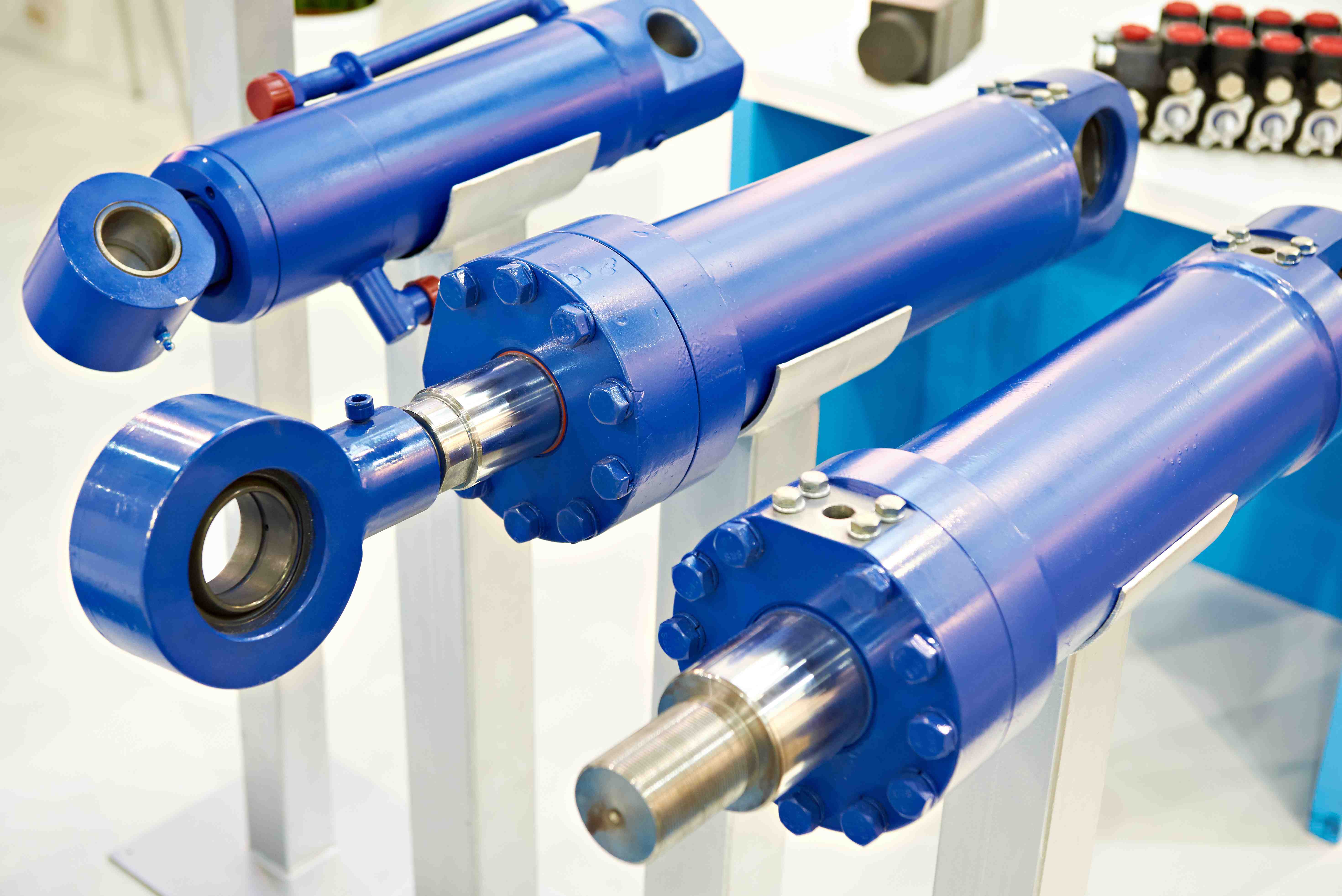

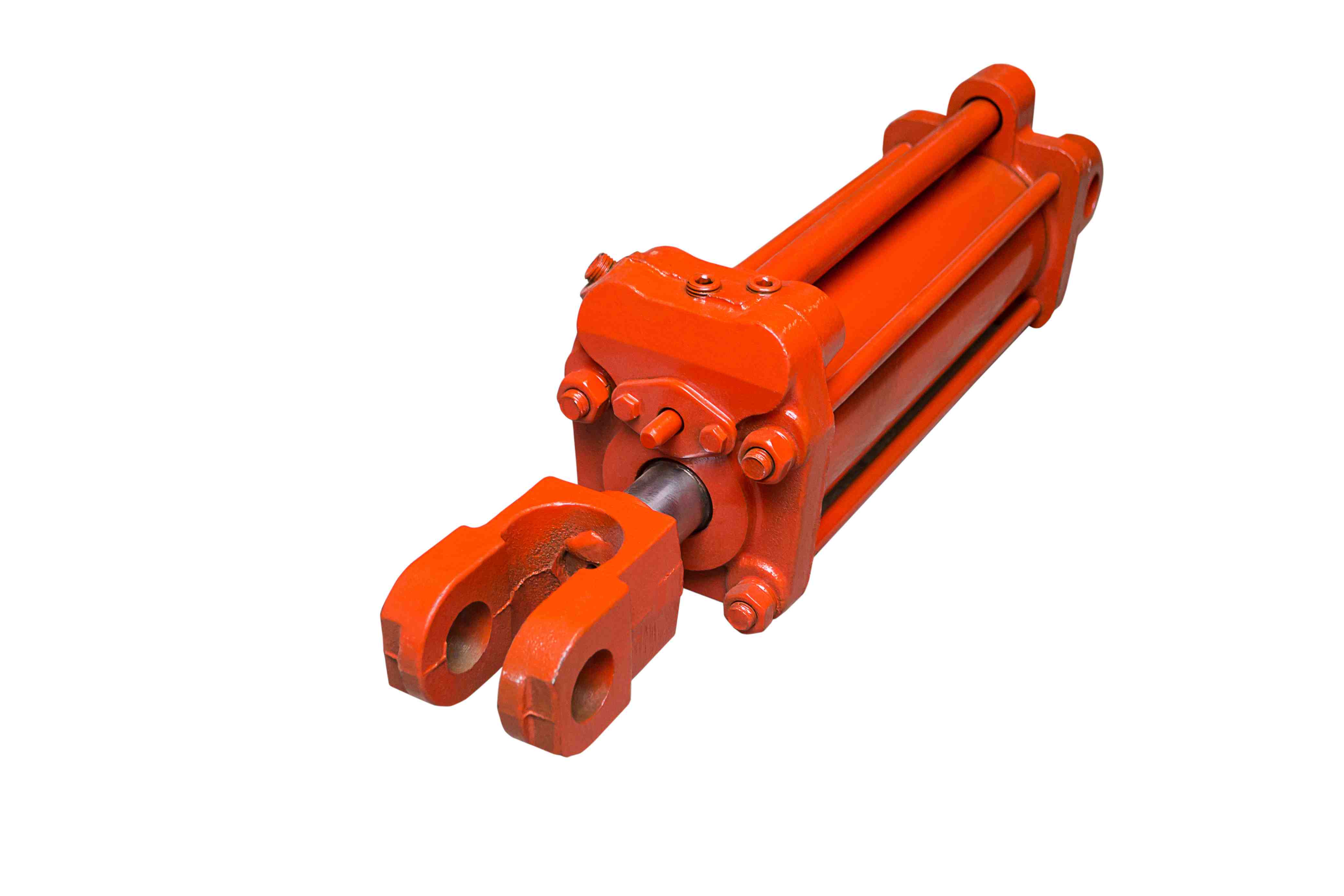

Hydraulic Components

The flexibility of sand casting allows for the production of both large and small-scale items, making it a widely used method in various industries.

Our Solutions

Investment Castings

Investment casting, also recognized as lost-wax casting, stands as an age-old yet highly effective method in metal formation. Our metalworks employ this technique, which is particularly suitable for crafting small to medium-sized castings. With capabilities extending to steel castings up to 600 lbs and aluminum castings up to 60 lbs, investment casting offers precision and versatility.

The process involves creating a ceramic mold from wax patterns, and after the wax is eliminated, molten steel is poured in, resulting in the desired casting. While it may incur higher unit costs than die casting, the investment casting process excels in shaping intricate designs that might pose challenges for other methods. Additionally, it demands minimal surface finishing and requires minimal machining in specific cases. At our metalworks, we extend investment casting benefits to aluminum and iron, ensuring diverse possibilities for our clientele.

The investment casting process is versatile and lends itself well to producing intricate and finely detailed metal components as opposed to die casting, which some companies lean toward.

Overall, the investment casting process is valued for its ability to produce parts with complex shapes, fine details, and tight tolerances, making it a preferred choice in industries where precision is essential.

Mining & Aggregate Industry Components

Oil & Gas Components

Compressor Components

Automotive Components

Hydraulic Cylinder and Actuator Components

Rolled Ring

Forgings

Die Forgings

Non-Ferrous Castings

Cast Irons

Steel Sand & Investment Castings

Elevate your casting experience with CAB – contact us now to unlock limitless possibilities for your business