Worldwide Quality Oversight

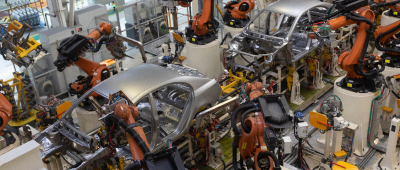

CAB Worldwide operates internationally with engineering and inspection teams on the ground across our entire supply chain. Our approach goes beyond order processing; we actively collaborate with partner factories, providing on-the-ground quality control and process improvement recommendations and oversight throughout production.

Comprehensive inspections are conducted at various stages – in-process, post-production, and final. These inspections utilize coordinate measuring machines to verify the quality of CAB’s parts and components. This process involves thorough documentation, including the results of PPAP (Production Part Approval Process) and FMEA (Failure Mode and Effects Analysis) testing. Additionally, CAB utilizes tools such as critical-to-quality trees and Gauge R&R (Gauge Repeatability and Reproducibility) studies and 8D and 5Y systems to further enhance our quality control measures.

Beyond Certifications

Secondary & Value Added Services

Worldwide Quality Oversight

Matrices of Capabilities by Material and Size

Design Engineering & Modeling

Domestic Machining Capabilities

Precision Machining Services

Our core values guarantee excellence worldwide, whether at home or abroad