Design for Manufacturing Recommendations & Modeling

Turn to CAB Worldwide for efficient Design for Manufacturing Recommendations & Modeling, engineering, and manufacturing expertise. We have a team of world-class experts in Design for Manufacturing (DFM) recommendations and modeling spread across multiple regions and countries. With our expertise, you can rest assured that your designs will undergo thorough evaluation, leading to valuable feedback aimed at enhancing manufacturability, saving you time and costs. Our proficiency extends across various processes, including casting, hot and cold forging, fabrication, precision machining, assembly, and welding, and covers a diverse range of material grades.

Comprehensive Design for Manufacturing skills, Engineering, and Testing Capabilities

CAB possesses the expertise and capabilities in Design for Manufacturing (DFM) recommendations and a diverse range of manufacturing techniques, complemented by our extensive testing capabilities and in-process inspection and error-proofing methodologies. This ensures that we uphold the highest standards of quality and reliability in every aspect of our manufacturing process.

3D Modeling & Advanced Simulation

We use cutting-edge 3D modeling software and simulations for our castings, expediting tooling, fixtures, gauging, and product development by accurately simulating metal flow and solidification processes.

Engineering Expertise

Using our Design for Manufacturing (DFM) recommendations and modeling reviews, we help customers refine their existing product designs to improve manufacturability, tooling efficiency, production speed, quality, and consistency.

Main Market Sectors

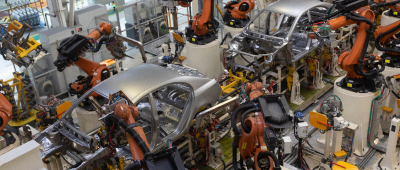

CAB’s expertise positions us as a leading supplier across many diverse sectors, including a base of major OEMS representing Hydraulics, Compressors, Automotive, General Industrial, Rail, Construction, Waste Removal, Towing & Transportation, and Agriculture industries.

Advanced Testing Techniques

CAB employs sophisticated manual and automated testing methods, including Material Destructive and Non-Destructive, Hardness, Ultrasonic, X-ray, Leak, and a variety of custom-designed tests guaranteeing the highest level of part quality and integrity.

Quality Assurance

CAB places a strong emphasis on quality, holding ISO 9001:2015 certification. We also ensure our partner facilities meet the rigorous standards of ISO 9001:2015 and/or IATF 16949 to maintain excellence in our products and services.

Procedures & Documentation

CAB rigorously maintains comprehensive documentation for both PPAP (Pre-Production Approval Process) and production shipments, covering material tests, dimensional inspections, manufacturing control plans, heat treatment verification, FMEA analyses, and PPAP outcomes to uphold the highest standards of quality and consistency.

Multidisciplinary Team

CAB boasts a highly skilled team with expertise in mechanical, electrical, and automotive engineering, metallurgy, foundry practices, casting, forging, gear cutting, and more.

Our team members are certified Six Sigma Black Belts and PMPs, with additional expertise in international business, supply chain management, and logistics.

Secondary & Value Added Services

Worldwide Quality Oversight

Matrices of Capabilities by Material and Size

Design Engineering & Modeling

Domestic Machining Capabilities

Precision Machining Services

Elevate your complex metal product experience with CAB – contact us now to unlock limitless possibilities for your business