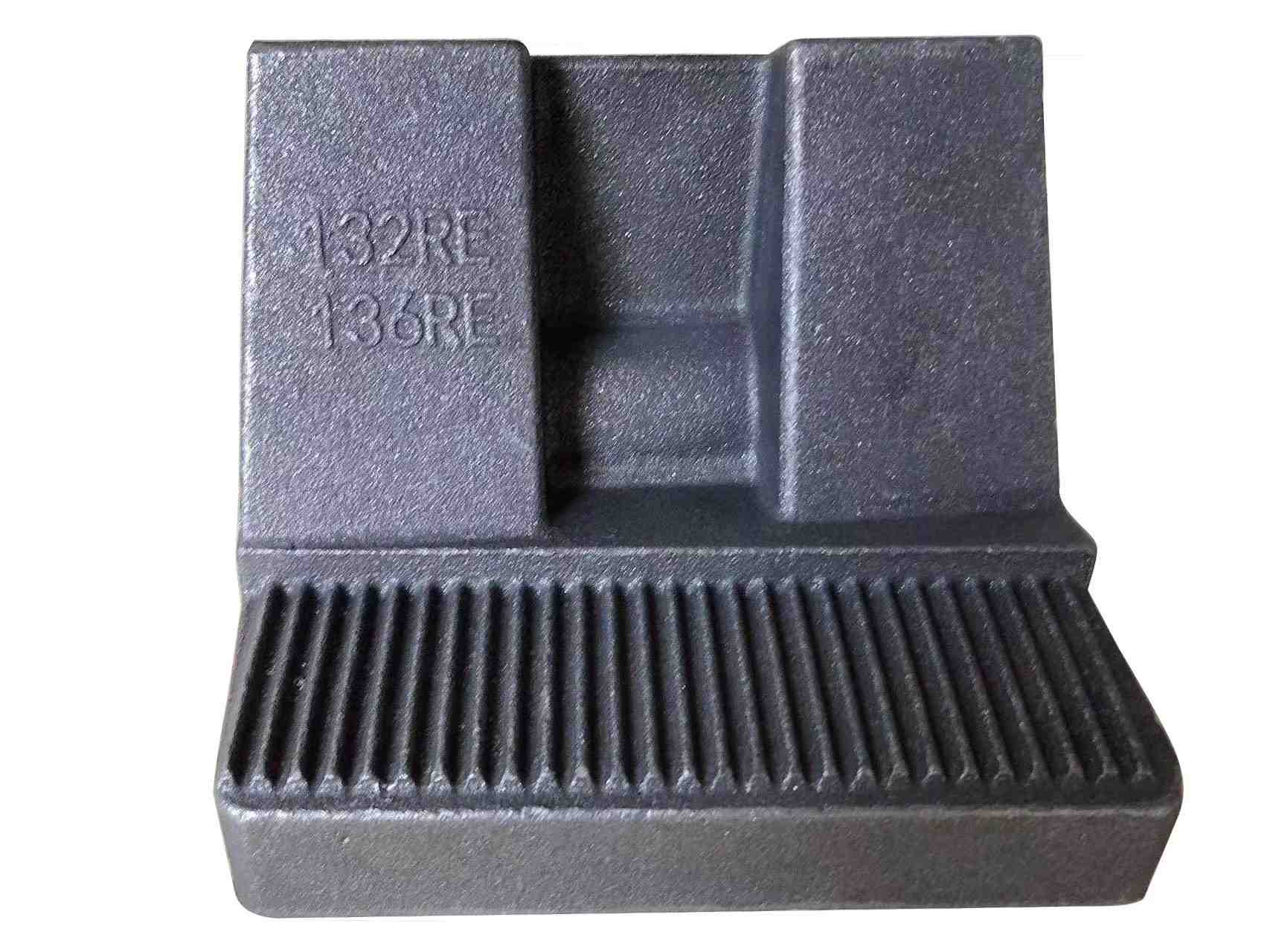

Reverse Engineering of Rail Brace

Recreating Designs for Legacy Components

Reverse engineering, in our context, refers to the process of reconstructing and documenting the original design and specifications of a product, particularly when drawings or other documentation are unavailable.

As a leading provider of industrial castings and forgings on a global scale, we encounter situations where customers lack legacy part drawings or require a redesign necessitating the documentation of the original product design.

For instance, we recently collaborated with a client unable to furnish drawings, CAD models, or material details for components no longer accessible from the original manufacturer.

The Outcome

Using advanced laser scanning technology, our team conducted a thorough reverse engineering study to generate parasolid models of the components. Afterward, we transformed these 3D models into detailed 2D drawings, incorporating dimensions and geometric tolerances needed for the manufacturing process. To verify material properties, we conducted rigorous metallurgical testing.

When finished with the reverse engineering process, the data can be used in computer models to assess part performance and manufacturability. Today, reverse engineering benefits significantly from cutting-edge tools like 3D scanning and computer modeling.

At CAB, our proficiency in diagnosing and reverse engineering customer products distinguishes us from competitors. We recently undertook the reverse engineering of an industry-standard rail brace.

Let us help you document those years of legacy knowledge