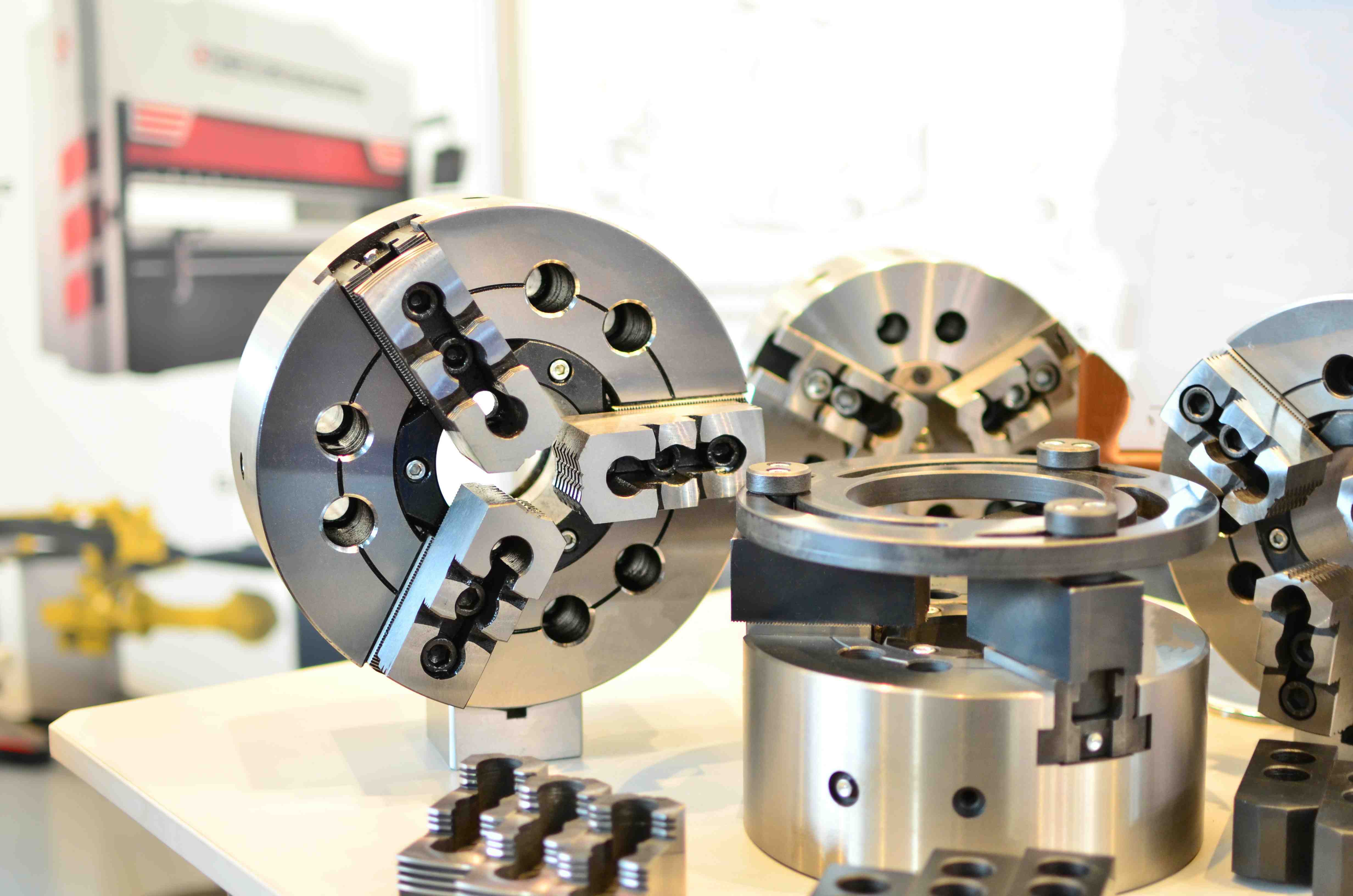

Custom Machine Fixtures

Design Assistance on Key Components for Mobile Refuse Collection

For over 40 years, CAB Worldwide has been a premier supplier of precision machining services, with expertise spanning casting and forging. When approached by a client in the mobile refuse collection industry, we were tasked with design recommendations, engineering, modeling, and machining a pivotal component: the arm pivot bracket.

We developed a custom, repeatable fixture to ensure seamless rotation during machining. Operating from 2D CAD drawings and utilizing ASTM A-487 GR 4A steel casting, our arsenal of vertical turning lathes, horizontal machining centers, and gantry lathes meticulously crafted the 6.218″ long, 2.5″ wide arm pivot bracket to exacting tolerances of ±0.03″.

Our commitment to precision extended to the finish, with a normalized and tempered surface reaching a roughness average of 63Ra. Rigorous testing and inspection, including tensile strength and carbon content analysis, affirmed the bracket’s durability and integrity, meeting strict quality standards.

The Outcome

Despite the project’s complexity, we expedited production, delivering 1,200 arm pivot brackets to Fort Payne, IN, four days after receiving the client’s approval.

At CAB Worldwide, our proficiency in machine tool design recommendation is exceptional. Clients benefit from our comprehensive suite of services, including SPC quality control analysis and Gauge R&R studies.

Are you interested in something similar? Contact us today to discover how our custom precision machining services can elevate your projects to new heights.

CAB provides deep knowledge in Fixture and Gauge Design to improve manufacturability